Mark Rober Sparks “Playful Anarchy” in the MIT Design Community

Jun 13, 2023

MakerLodge is an extracurricular training program teaching making skills open to all MIT first-year undergraduate students. It’s a great way to discover MIT shops and makerspaces, use manual and digital tools, socialize, and appreciate the power of making for experiential learning. By making a couple of small objects using a range of equipment such as a drill press, a laser cutter, or a 3D printer, students receive orientation and safety training. It’s an exciting first step to explore the many possibilities within the MIT making and design community.

By Adelaide Zollinger

Sep 26, 2023

SEPTEMBER 2024 UPDATE:

MAKERLODGE IS NOW M1T, "MAKERSPACE FIRST-YEAR TRAINING."

First-Years may sign up through this link.

Making and prototyping shape the way we approach innovation and nurture real-world readiness. Transcending disciplines, they are pivotal in (design) education for their ability to transform abstract ideas into tangible creations and artifacts. Hands-on practices develop a mindset of engaging with trial and error, exploration, and iteration, contributing to a profound understanding of the design process. It allows students to acquire essential skills for the professional world, by encouraging problem-solving, user-centered approaches, and risk mitigation. In the shops, students also experience collaborative learning, enhanced creativity, and get to demonstrate craftsmanship.

Sabrina H. works on her laser cut project of a map of Barcelona.

Photo: courtesy of Project Manus

Yet, going to a makerspace for the first time can be intimidating. Several shops and makerspaces at MIT welcome beginners without prior experience. Project Manus, a part of the MIT Morningside Academy for Design (MAD), provides spaces, equipment, training, and project ideas, fostering maker communities across the Institute. It operates two spaces on campus, Metropolis, and The Deep, where experienced student mentors provide training to MIT community members.

Those interested in making don’t need ideas or projects to get started, since mentors and classmates can help explore possibilities without prerequisites. MakerLodge is an extracurricular peer-to-peer training program initiated by Prof. Martin Culpepper with the goal of training every incoming first-year undergraduate on introductory maker technology. It also welcomes transfer students in their first year at MIT, and is an ideal launchpad to get started through hands-on exploration.

Trang L. utilizes the bandsaw with proper eye and ear protection, which is an important part of makerspace safety.

Photo: courtesy of Project Manus

Students are required to attend a 30-minute orientation, touring the Metropolis makerspace and reviewing its policies, after which they can sign up for one or both of two available tracks of MakerLodge training: digital, and manual fabrication. In both, students are given hands-on training in small groups by experienced upperclassmen who serve as mentors. “What's nice about the program is that it's all taught by other students, so they also get to meet some of their peers, and learn what it's like to just work in the makerspace and be part of that community,” explains Jess Osserman, the maker technical specialist running the program.

On the digital fabrication track, students learn how to use a laser cutter and FDM (fused deposition modeling) 3D printer; the manual fabrication track teaches them how to use the bandsaw, drill press, and sander.

Actually using the bandsaw made the machine a lot less intimidating,” commented a trainee, adding that “the mentor was very encouraging, which made it feel like a safe space for making mistakes.

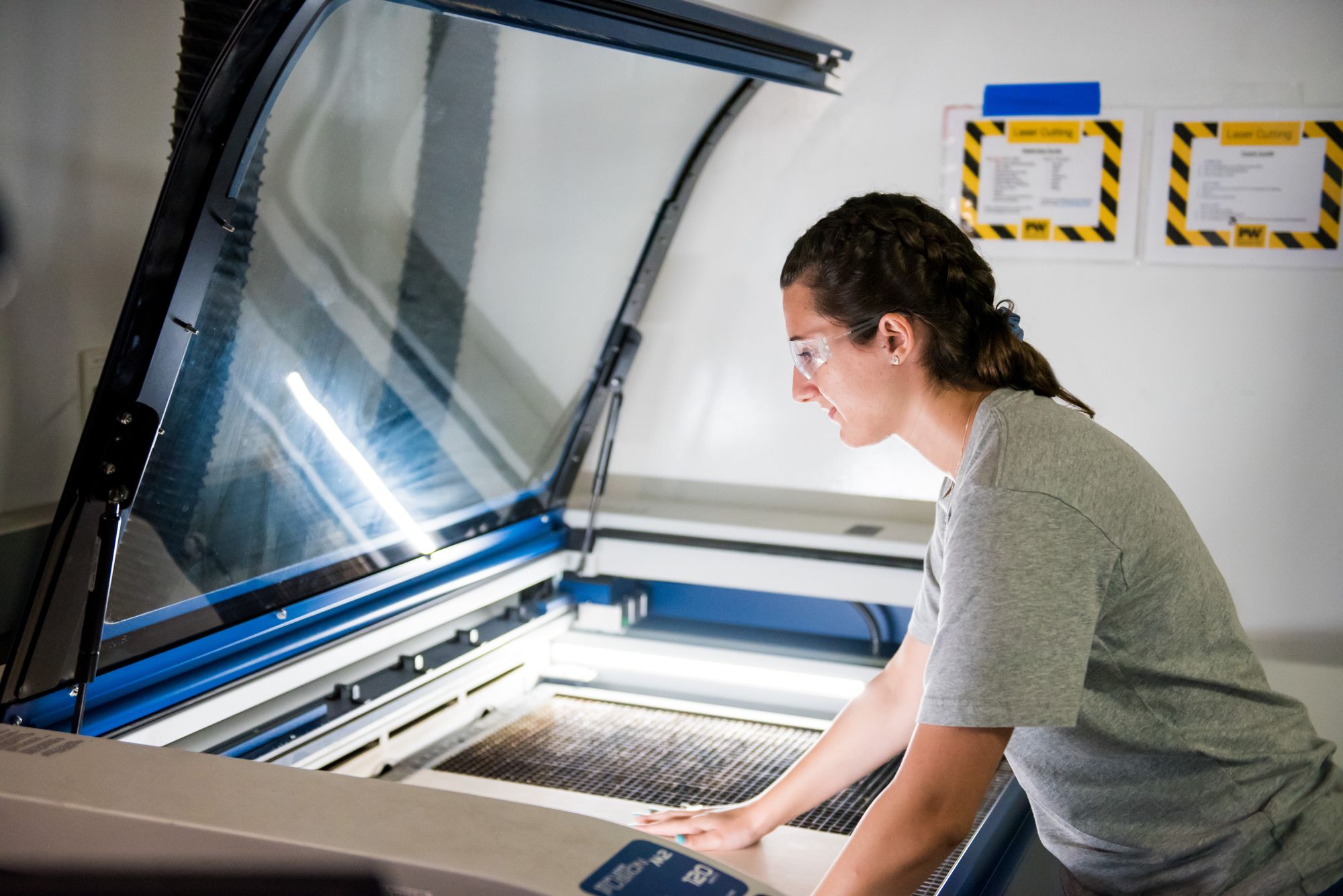

Thérèse M. uses the laser cutter, a tool taught on the Digital Fabrication track of MakerLodge.

Photo: courtesy of Project Manus

In both cases, the objective of the training is for students to learn how to use the tools by designing and making a small object to take home.

I think what students really like is getting to do hands-on work right away. They don't have to sit through a long lecture, and can start making within the first minute. That’s really fun for them,

notes Osserman. They can then come back to Project Manus spaces to work on personal, class, or research projects during Open Hours. “This year, we had over a hundred students come back at least once more to make things,” Osserman remarks.

To get started, a lot of students download designs from Thingiverse, a website dedicated to the sharing of open-source user-created digital design files. Osserman explains: “You can find all sorts of things. Typically, students tend to make something very small, like an articulated beaver or a fidget toy. After training, our graduates use the 3D printers to make everything from prototypes of machine parts to costume accessories like crowns and telescoping light sabers.”

Student projects after a MakerLodge Manual Fabrication training focusing on Bandsaw and Drill Press.

Photo: Project Manus student mentor Kanokwan Tungkitkancharoen '25

Following the program, students are emailed a study guide and online quiz. Once completed, they can pick up a toolbox, MakerLodge T-shirt, and earn MakerBucks, the official currency that students can use to purchase materials from the shop, such as acrylic or plywood for laser cutting. After completing one track, many students come back to complete the other.

In its effort to elevate making at MIT, Project Manus recently developed a whole website dedicated to making and prototyping, make.mit.edu. It allows students to find makerspaces, locate equipment, sign up to learn skills, find inspiration, and access all kinds of useful resources such as materials, calendars and maps. Happy making!

Jun 13, 2023

Aug 23, 2023

Feb 15, 2023